Simulation analysis from AutoCAST offers temperature history, liquid metal fraction, solidification time, cooling curves, and air fraction. Major defects like misrun cold shut, air blow hole, shrinkage porosity, and hard zone can be predicted. Free addons and downloads for Lockheed Martin Prepar3D, P3D, Microsoft Flight Simulator and Flight Sim series. 1000's of freeware addons for your Flight Simulator! Over 4000 pages of free downloads. More free addon planes than any other site! Complete aircraft. Casting Simulation software, free download World Of Warships Advenger 2800st Service Manual Drivers Brother Hl L2380dw Windows 7 Ultimate 64 Bit Sp1 Programming Visual Basic 2010 Pdf Battlefield 3 Crack Megaseg Apple Music Microsoft Cleanup Utility Tool Windows 10 Free Chess Game For Windows Rules Of Thumb Pdf.

Infrastructure

World class modern infra to produce Global quality castings.

- Premises

- Pattern shop

- Core shop

- Melting

- Fettling

- Quality Lab

Premises

Foundry Premises

Machine Shop Premises

Machine Shop Premises

- Total Land Area: 30,000 Sq Meters

- Foundry Office Area: 1000 Sq Meters

- Foundry Work Area: 15000 Sq Meters

- Machine Shop Office Area: 1000 Sq Meters

- Machine Shop Work Area: 3000 Sq meters

- A full fledged office with dedicated departments for Marketing, Sales , Finance & Accounts, Purchase, Production, Quality, and Logistics.

Pattern shop

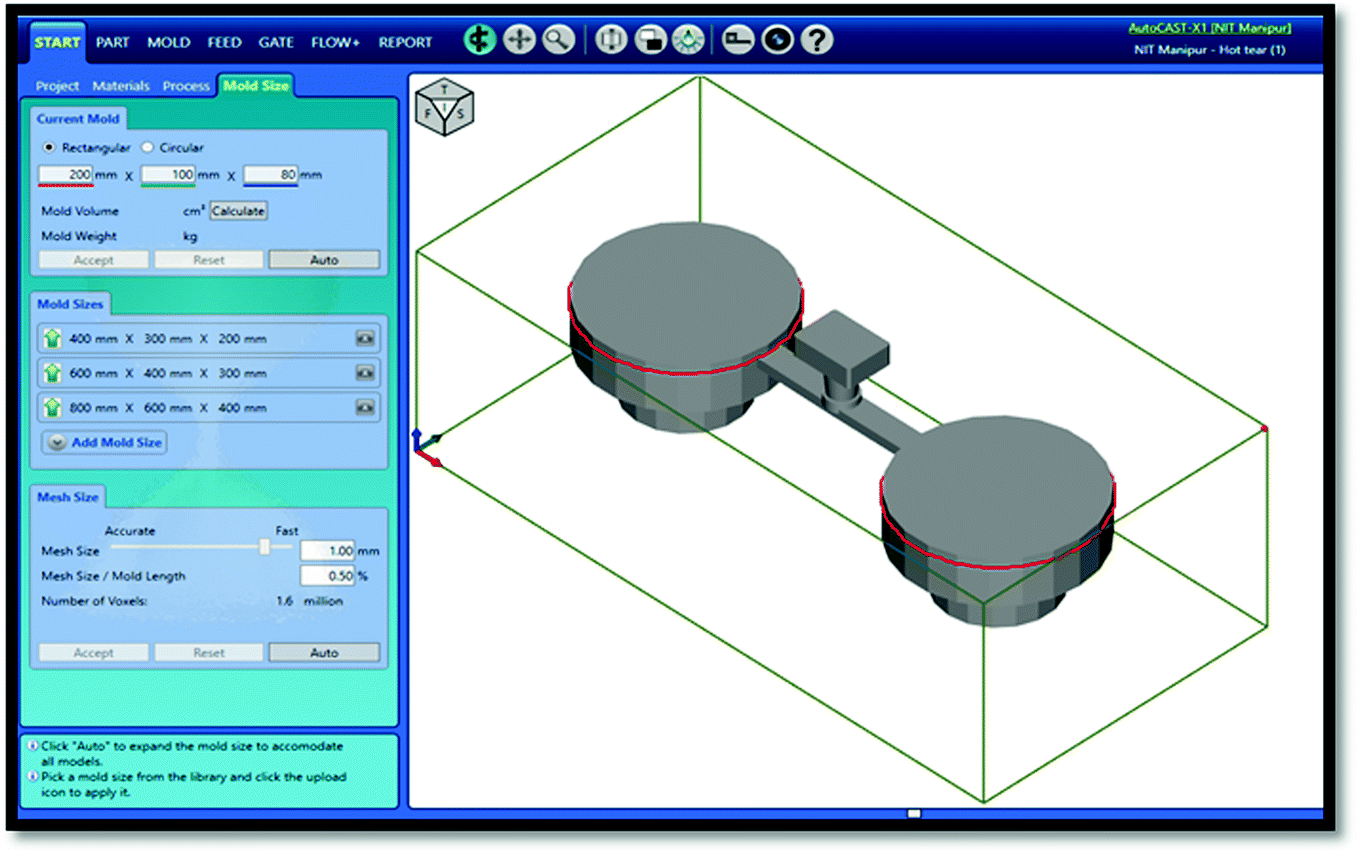

- Tooling Development is supported with CAD / CAM & AUTOCAST - Simulation Software facilities which minimizes the development time .

- We are capable of submitting all parts with APQP, FMEA, CONTROL PLAN, SPC,MSA,PSW,PPAP.

- In house facility for undertaking the Mounting of patterns followed by methoding and rework wherever required.

- Two numbers of Lathes, one Milling machine, one Cutting machine, Surface table, Height gauge, and Digital Vernier exclusively for handling pattern shop activities

- Coordinate Measuring Machine (CMM ) to inspect the First sample dimensions whenever required

Core shop

- A Shell Core Shooter of 5Kg capacity

- 3 Nos of Cold Box Core Shooter of 5Kgs, 10Kgs and 15 Kgs capacity

- Co2 Core making facility with 8 tables

- Heating Oven for baking of cores

- 2 nos x 250kgs Core Sand Mixer

- 2 Ton/hour capacity Core Sand Drier

Melting

- 2 Nos of Medium Frequency Induction Furnace with 600 KW capacity each of Inductotherm make

- Each of the above furnace has 2 Nos of 1 Ton Crucible

- 3 Ton EOT Crane with 250Kgs and 500Kgs Treatment ladles

- Mono Rail system for Pouring

- 4 Nos of 500 Kgs Ladles for magnesium treatment for Ductile Iron

- 12 numbers of SOHGS Hand Shanks.

- Dust collector facility for environmental protection

Fettling

- Hydraulic wedge cutting machine for breaking runner and riser

- Two numbers of 500 Kgs capacity shot blasting machine.

- 8 numbers of Bench grinders and 2 Nos of Swing frame grinders supported by combination of pneumatic grinders.

- Trimming Machine of 60 Tons capacity

- Tumble blasting machine of 300 Kg Capacity for cleaning of components

- Nozzle Blasting machine to clean intricate and complex core holes

Testing facilities

- Spectrometer: ARL (Swiss) make 29 element analyzer

- Image Analyzer with Camera Attached to Microscope

- Sand Testing Equipments

- Tensile & Hardness Tester

- CEE Meter

- Charpy impact tester

Automobile Part

Manifold Pipe

Railway Insert

Axle Box Housing

Brake Drum

Magnetic Frame

Breaker Oil Tank

Coolant Pipe

Ring Casting

Connection Water Inlet

Gear Case

Pressure Bowl

Jewellery Ring

Autocast Simulation software, free download

Analysis of Pump Body Casting by using Casting Process Simulation

Gating System and Feeder Design of Aluminium Alloy (AA6063) Casting for Rectangular Component

Gating Design Optimization for Improvement in Yield of Casting

Generation of Optimum Parting Lines for Metal Cast Parts

Simulating the Effect of Gating Design and Pouring Temperature on LM4 Casting Quality

Optimization of Riser Neck for Aluminium Casting by using Simulation Tool

Application of 3D Cad Modeling and Casting Simulation to Eliminate Casting Defects.

Design Optimization of Gating and Feeding System through Simulation Technique for SandCasting of Wear Plate

Optimized Design of Risering System for Casted Component by Using Web Based Online Simulation E-Tool

Optimization & Experimental Validation of Feeding System for Steel Casting Using Traditional and Simulation Technique- A Case Study

Critical Analysis of Rapid Prototyping assisted Investment Casting for Medical Implants

Analysis & Simulation of Casting to Eliminate Casting Defects

Minimization of Gas Porosity through Casting Simulation Tool for Sand Casting

Warpage Simulation of Manhole Cover using AutoCAST-X Software

Indigenous Development and Industrial Application of Metal Casting Simulation Software

Casting Design and Simulation of Cover Plate using AutoCAST-X Software for Defect Minimization with Experimental Validation

Minimization of Shrinkage Porosity in A Sand Casting Process By Simulation In AUTOCAST-X Software with Experimental Validation by Destructive testing

Methoding and Simulation of LM 6 Sand Casting for Defect Minimization with its Experimental Validation

Feeder Design and Analysis by Casting Simulation Software

Design Optimization of Feeding System and Solidification Simulation for Cast Iron

Riser Design Optimization based on Feeding Rules using 3D CAD Modelling and Casting Simulation

Optimization of Casting Process Parameters through Simulation

Analysis and Optimization of Gating System for TVS SATELITE

Multi-Physics Simulation and Casting Defect Prediction Using FLOW+

Autocast Simulation software, free download 2012

Rapid Development of Industrial Castings Using Computer Simulation

Autocast Simulation Software free. download full Version

Innovative Simulation of Castings – A Technology to Improve Quality of Castings as per Global Specifications with Case Studies

Feasibility Study of Manufacturing using Rapid Prototyping: FDM Approach

Autocast Simulation software, free download Windows 10

Feeding System Design and Evaluation using Temperature Gradient (Feed Path) Maps